Titanium is a premier material prized across high-stakes industries like aerospace, chemical processing, and medical devices for its exceptional strength-to-weight ratio, biocompatibility, and unparalleled corrosion resistance. However, unlocking these benefits requires a deep understanding of its unique properties. Custom titanium fabrication is a highly specialized field that demands expert knowledge, dedicated equipment, and pristine working conditions to prevent contamination and preserve the material's integrity.

At FABRI-TEK ENGINEERS, we are a leading titanium fabrication company in India. With extensive experience and a team of dedicated experts, we provide high-quality, custom-fabricated titanium components and assemblies that meet the most stringent international standards and demanding client specifications.

Our Comprehensive Titanium Fabrication Capabilities:Precision Cutting: We utilize advanced cutting technologies, including waterjet and laser cutting, to achieve clean, burr-free edges on titanium sheets, plates, and bars without creating a heat-affected zone.

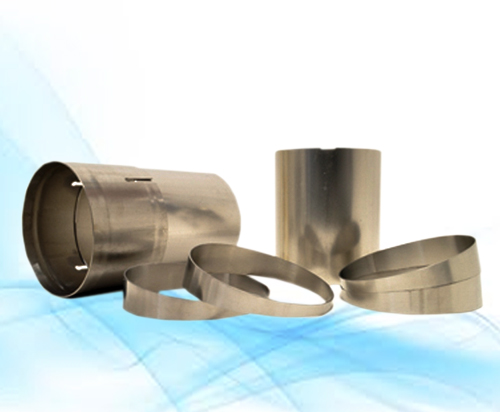

Specialized Forming: Our skilled technicians are adept at forming titanium into complex geometries using methods like rolling, press braking, and hydroforming, carefully managing springback and temperature to maintain material properties.

Expert Titanium Welding: We employ advanced welding techniques, primarily Gas Tungsten Arc Welding (GTAW or TIG), in an inert argon-purged environment. This critical process prevents atmospheric contamination, ensuring strong, ductile, and corrosion-resistant welds.

High-Precision Machining: Our CNC machining centers are equipped with specialized tooling, coolants, and optimized software programs designed specifically for the challenges of titanium machining, allowing us to deliver components with exceptionally tight tolerances.

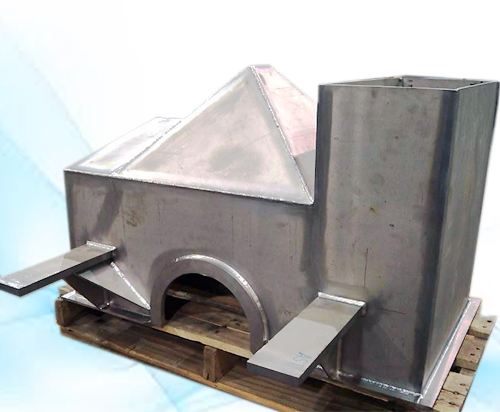

Meticulous Assembly: Our skilled engineers and technicians assemble complex titanium structures and components, ensuring perfect fit-up and adherence to all design requirements for a flawless final product.

As one of the top titanium fabrication manufacturers, our services are vital to a range of industries:

Aerospace & Defence: We fabricate mission-critical titanium parts such as engine components, airframe structures, fasteners, and landing gear, where light weight and high strength are paramount.

Chemical Processing: We are trusted titanium fabrication suppliers for the chemical industry, building robust equipment like reactors, heat exchangers, piping, and vessels that can withstand highly corrosive environments.

Medical Devices: We manufacture biocompatible titanium components for medical applications, including surgical implants (e.g., hip and knee joints), precision surgical instruments, and housings for medical equipment.

Uncompromising Quality Control and Certification:

Our commitment to quality is absolute. We maintain a stringent quality control program to ensure every titanium fabrication meets the highest standards of quality, safety, and reliability.

Material Testing & Verification: We conduct comprehensive material testing, including Positive Material Identification (PMI), tensile testing, and corrosion testing, to verify that the titanium (e.g., Grade 2, Grade 5) meets all required specifications.

Dimensional Inspection & NDT: All fabricated components undergo rigorous dimensional inspection using precision instruments. We also perform non-destructive testing (NDT) like Dye Penetrant Testing (DPT) and Radiography on welds to ensure they are free of defects.

Harness the full potential of titanium with a fabrication partner who understands its complexities. At FABRI-TEK ENGINEERS, we combine state-of-the-art technology with deep expertise to deliver superior titanium components and assemblies for the most demanding applications. Contact us today to discuss your project and learn more about our world-class titanium fabrication services.