At FABRI-TEK ENGINEERS, we are specialists in the fabrication, supply, and installation of high-quality **process piping systems**. Our expertise serves critical sectors like oil and gas, chemical processing, power generation, and water treatment. We provide precision-engineered process piping solutions that are tailored to the unique demands of each project, ensuring safety, reliability, and optimal performance.

What is Process Piping Fabrication?

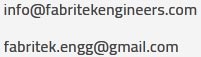

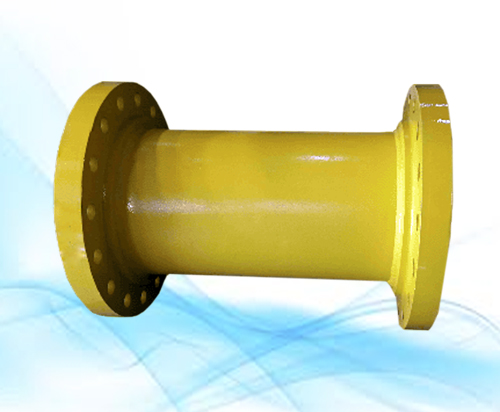

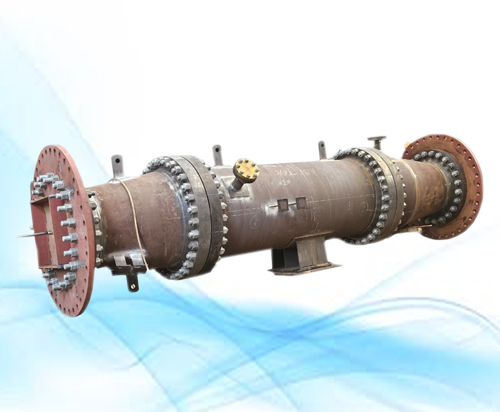

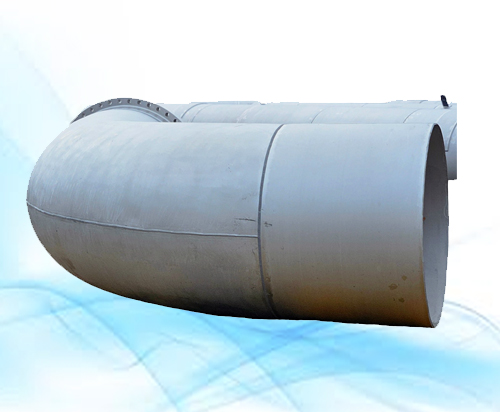

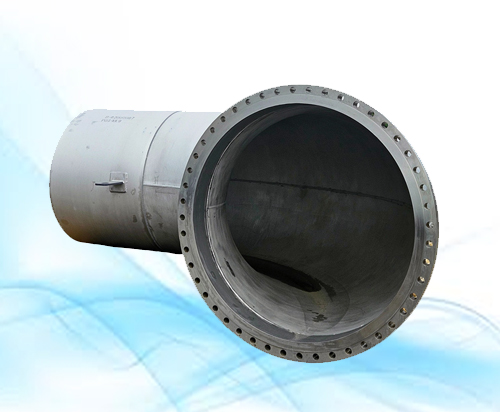

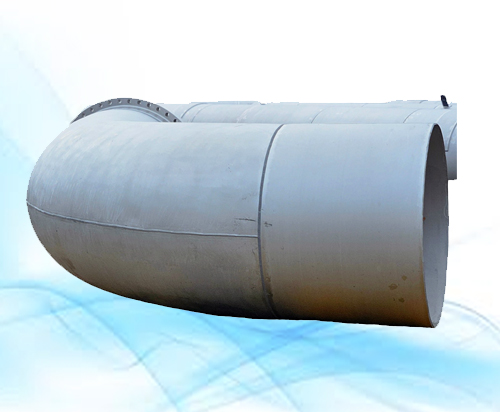

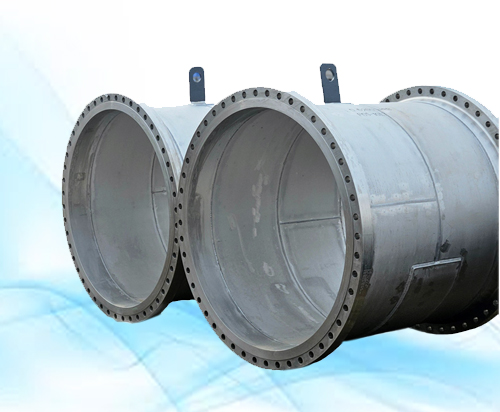

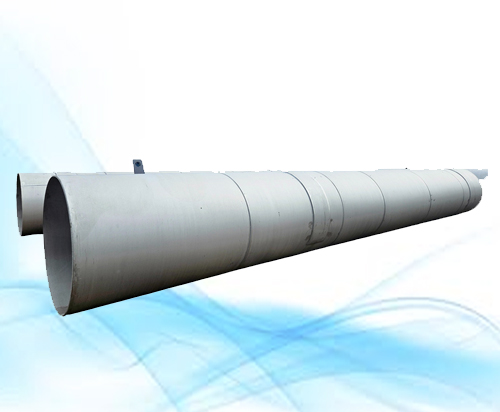

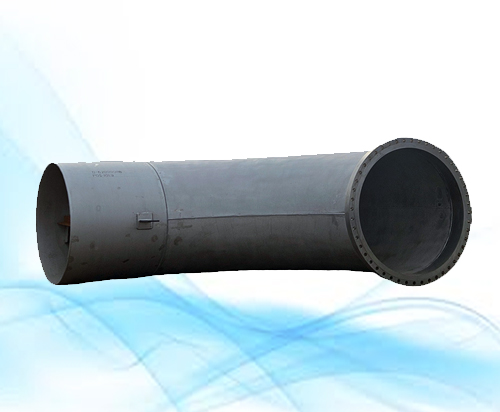

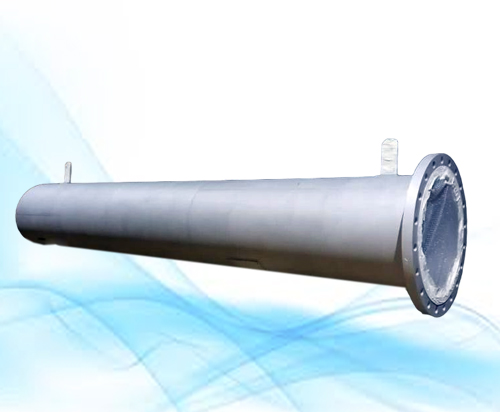

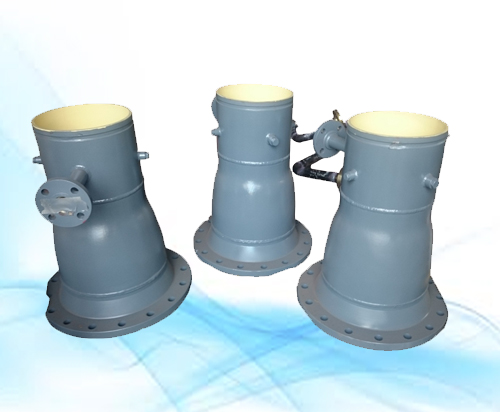

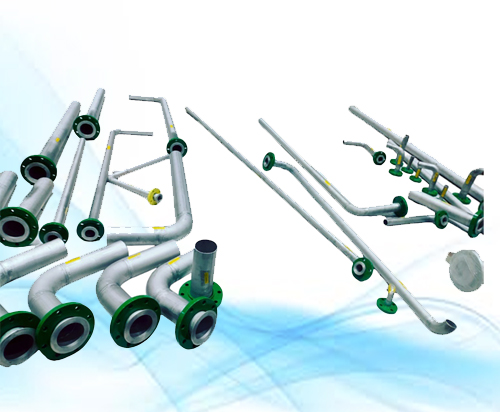

Process piping fabrication is the essential process of creating intricate piping networks that transport fluids, gases, and slurries in industrial settings. This involves the precise fabrication of various piping components, including pipes, fittings, flanges, and valves, which are then assembled into complete, robust systems. Our piping spool fabrication and assembly processes utilize cutting-edge machinery and skilled technicians to guarantee exceptional precision and accuracy.

Materials : We utilize a wide range of high-quality materials to ensure durability and resistance to harsh operating environments. Our materials include carbon steel, stainless steel, duplex, super duplex, Inconel, Hastelloy, alloy steel, titanium, aluminum, and exotic alloys, selected based on specific application requirements.

Our Process Piping Solutions

Custom Piping Systems : We design and fabricate custom process piping systems to meet the exact specifications of our clients, including unique sizes, materials, and complex configurations for seamless integration into existing facilities.

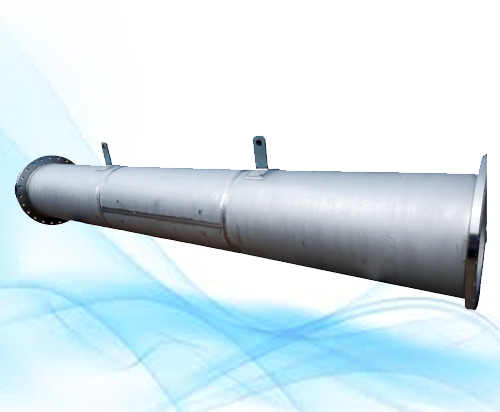

High-Pressure Piping : Our high-pressure piping solutions are engineered for demanding applications in oil and gas and power generation, designed to withstand extreme pressures and temperatures while maintaining absolute safety.

Choosing our process piping offers several distinct features and benefits, including:

Precision Engineering : Our piping is engineered for accurate fit, perfect alignment, and minimal on-site adjustments, significantly reducing installation time and costs.

High-Quality Materials : By using only the best materials, we ensure superior durability, corrosion resistance, and a longer operational lifespan for your piping infrastructure.

Customization : We provide fully customized solutions to address the specific challenges and requirements of your project, from simple to highly complex designs.

Improved Safety & Efficiency : Our robust and leak-proof piping systems are designed to enhance operational safety, reduce the risk of accidents, and minimize costly downtime.

Applications : Our industrial piping fabrication solutions are trusted across a variety of industries, including:

Oil and Gas : We supply piping for a wide range of applications within oil refineries, petrochemical plants, and natural gas processing facilities.

Chemical Processing : Our process piping is a vital component in chemical plants, fertilizer facilities, and pharmaceutical manufacturing, ensuring the safe transport of critical materials.

Power Generation : We provide essential piping systems for fossil fuel-based and nuclear power plants, engineered to handle the intense conditions of electricity generation.

Water Treatment : Our piping solutions are integral to the infrastructure of water treatment plants, including desalination and wastewater treatment facilities.

Quality Control and Testing : Quality is our top priority. We adhere to stringent quality control standards and employ a comprehensive range of testing methods to ensure every piping system meets the highest industry and safety standards. Our rigorous processes include:

Visual Inspection : Our certified inspectors perform detailed visual examinations of all process piping for any surface defects or imperfections.

Non-Destructive Testing (NDT): We use advanced NDT techniques such as penetrant testing, radiography, ultrasonic testing, and magnetic particle testing to detect internal defects and flaws without damaging the material.

Hydrostatic Testing: Each fabricated pipe is subjected to a hydrostatic pressure test to confirm its structural integrity and ability to withstand the designed operating pressure.

Material Testing: We conduct comprehensive material testing, including tensile and impact testing, to verify that the materials used meet all required specifications and codes.

Certification and Compliance : All our process piping systems are designed, fabricated, and tested in strict accordance with relevant industry standards and regulations, such as ASME B31.3 and other applicable codes. We partner with reputable third-party inspection agencies to ensure full certification and compliance, providing our clients with complete peace of mind.

At FABRI-TEK ENGINEERS, we are committed to providing high-quality process piping fabrication solutions that meet the specific requirements of our clients. Our extensive expertise in piping engineering, manufacturing, and testing ensures that our products provide precision-engineered solutions for a vast range of industrial applications. We are your reliable partner for process piping, delivering solutions that stand the test of time. Contact us today to learn more about our comprehensive process piping fabrication solutions and how they can benefit your business.