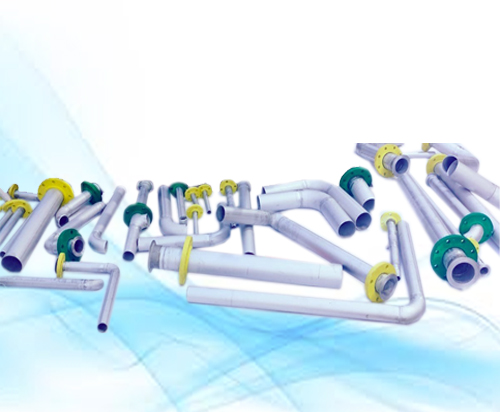

What is Prefabricated Piping?

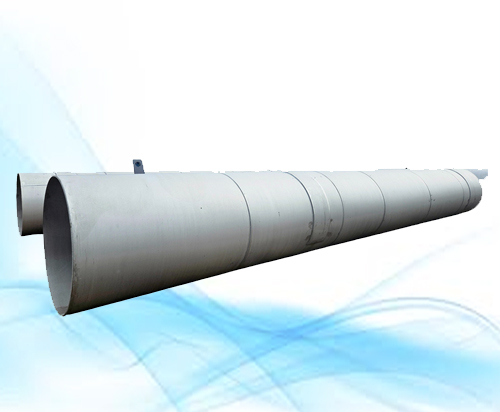

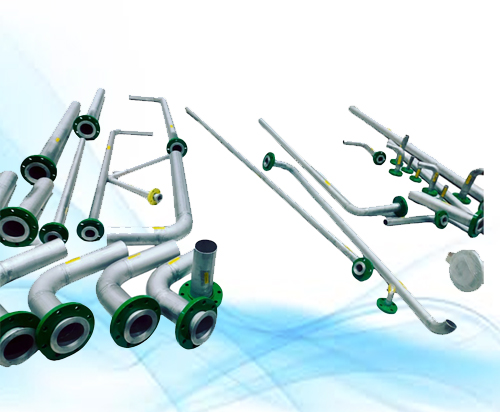

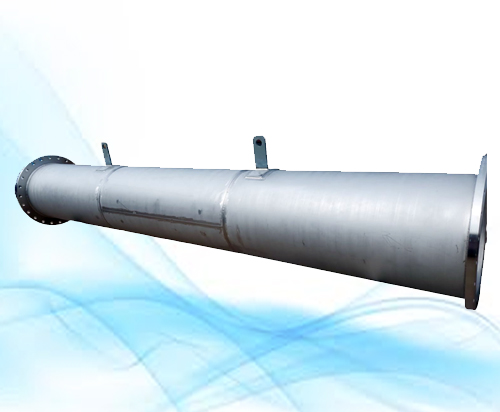

Prefabricated piping refers to the assembly of piping components—including pipes, fittings, flanges, and valves—into a complete piping system or

pipe spools within a controlled workshop environment. This advanced approach significantly improves quality, reduces on-site installation time, and enhances overall project safety and efficiency. Our

prefabricated piping is manufactured using state-of-the-art machinery and welding techniques to ensure unparalleled precision and accuracy.

Materials for Our Prefabricated Piping Solutions

As a trusted

prefabricated piping supplier, we fabricate our products using a variety of high-quality materials to ensure durability, corrosion resistance, and suitability for specific applications. Our material expertise includes:

- Carbon Steel

- Stainless Steel (304, 316, etc.)

- Duplex and Super Duplex Steels

- Inconel and Hastelloy Alloys

- Alloy Steel

- Titanium

- Aluminium and other exotic alloys

Our Prefabricated Piping Capabilities

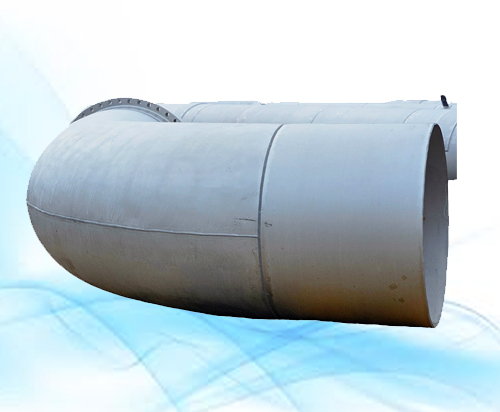

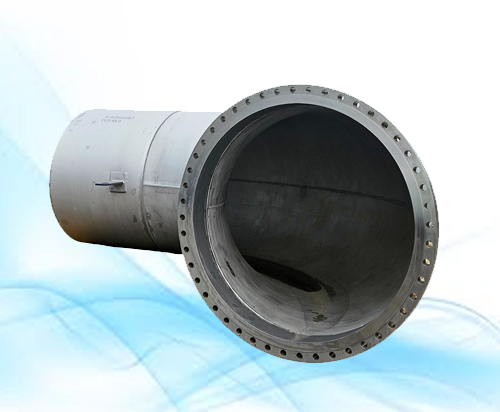

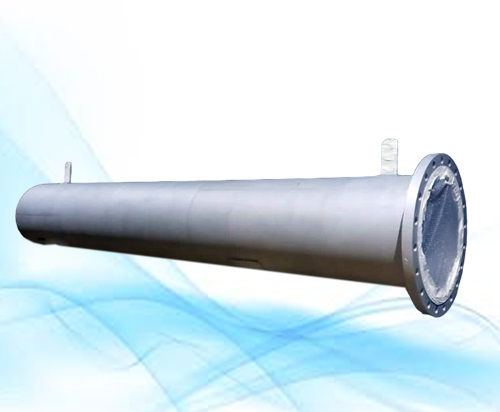

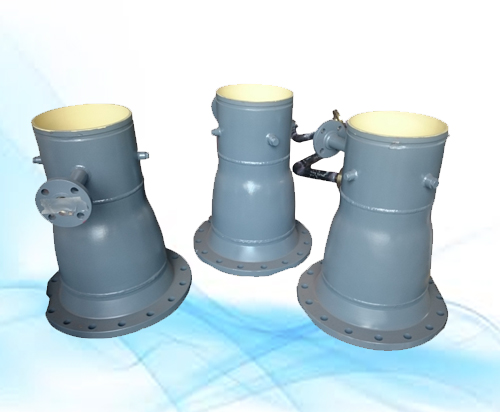

Custom Prefabricated Piping Systems: Our custom prefabricated piping is designed to meet the unique and specific requirements of our clients. We offer tailored solutions for a variety of sizes, materials, and complex configurations.

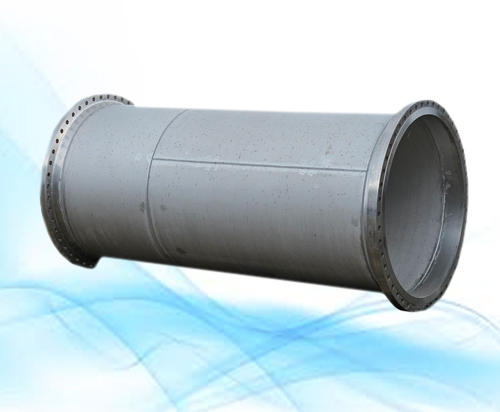

High-Pressure Piping: We specialize in high-pressure prefabricated piping engineered for demanding applications in the oil & gas, petrochemical, and power generation sectors, ensuring maximum safety and performance.

Industries We Serve

Our prefabricated piping solutions are used across a diverse range of industries, including:

- Oil and Gas: Critical for refineries, petrochemical plants, and natural gas processing facilities.

- Chemical Processing: We are a key piping supplier for chemical, fertilizer, and pharmaceutical plants.

- Power Generation: Essential for fossil fuel-based and nuclear power plants.

- Water Treatment: Providing durable piping systems for desalination and wastewater treatment facilities.

Quality Control and Testing at FABRI-TEK ENGINEERS

Quality control is a fundamental part of our prefabricated piping manufacturing process. We use a comprehensive range of testing and inspection methods to ensure our products meet the highest standards of quality and safety. These methods include:

- Visual Inspection: Our certified inspectors perform meticulous visual examinations to detect any surface defects or imperfections.

- Non-Destructive Testing (NDT): We use advanced techniques like penetrant testing, radiography, ultrasonic testing, and magnetic particle testing to identify any internal flaws or defects in the piping.

- Hydrostatic Testing: Every prefabricated piping spool is subjected to a hydrostatic pressure test to confirm its ability to withstand the specified operating pressure.

- Material Testing: We conduct rigorous material testing, including tensile testing, impact testing, and corrosion testing, to ensure all materials comply with the required specifications.

Certification and Compliance

Our

prefabricated piping is manufactured to meet all relevant industry standards and regulations. We collaborate with accredited third-party inspection agencies to ensure our products and processes comply with all necessary certification and compliance requirements, giving you complete peace of mind.