Our expertise in evaporator heat exchanger manufacturing allows us to provide efficient and reliable heat transfer solutions specifically designed to meet your project's unique requirements. We are committed to producing industrial evaporators that enhance process efficiency and reduce operational costs.

What are Evaporator Heat Exchangers? An evaporator heat exchanger is a type of heat exchanger used to convert a liquid into a vapor. This phase change is achieved by transferring heat from a secondary fluid—typically water or air—to the process fluid, often a refrigerant. The resulting vapor is then utilized in various systems, including refrigeration, air conditioning, and power generation cycles.

Design and Manufacturing Process Our evaporator heat exchangers are meticulously designed using advanced engineering software and manufactured with state-of-the-art machinery to ensure precision and accuracy. Our design process includes:

Our experienced engineers use industry-leading software like HTRI to perform detailed thermal design, considering critical factors such as fluid properties, flow rates, and pressure drops to optimize heat transfer.

The mechanical design involves careful selection of materials, tube layout, and shell design to ensure optimal performance, structural integrity, and long-term durability. We design for robust operation under demanding conditions.

We manufacture our industrial evaporators using a wide range of high-quality materials, including carbon steel, stainless steel, aluminum, duplex, super duplex, Inconel, hastelloy, alloy steel, titanium, and other exotic alloys, chosen to suit your specific application and environment.

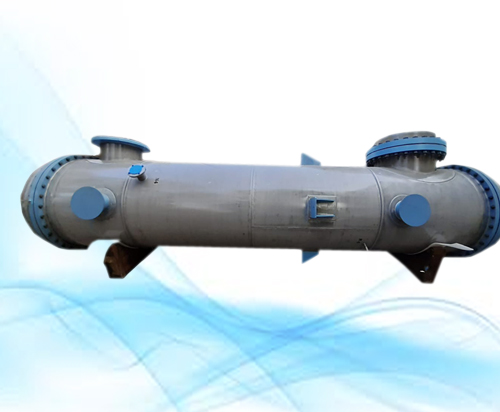

Shell and Tube Evaporators: We specialize in shell and tube evaporators, which are a reliable and robust choice for high-pressure and high-temperature applications. These are commonly used in power plants and chemical processing facilities due to their proven design and durability.

Our evaporator heat exchangers are engineered for performance, offering several key features and benefits:

High Heat Transfer Efficiency: Our evaporation heat exchanger designs are optimized for high heat transfer rates, leading to improved process efficiency and significant energy savings.

Our evaporator heat exchangers are utilized in a variety of industrial sectors, including:

We maintain strict quality control measures to ensure that every evaporator heat exchanger meets or exceeds international standards and client specifications. Our comprehensive quality control process includes:

Our evaporator heat exchangers are designed and manufactured in compliance with major industry standards and regulations, including TEMA, ASME U Stamp, Pressure Equipment Directive (PED) (2014/68/EU), and TRCU Certification. We work with third-party inspection agencies to ensure all our products meet these stringent certification requirements.

At Fabri-Tek Engineers, we are dedicated to providing high-quality evaporator heat exchangers that are perfectly suited for our clients' needs. Our extensive expertise in design, manufacturing, and rigorous testing ensures that our products offer efficient, reliable, and cost-effective heat transfer solutions across various industries. Contact us today to learn more about our custom solutions and how we can benefit your business.